Content

- Why Precast? (Advantages) - thin brick formliners

- Reference Pictures - thin brick form liners

- Full Overview Of Attractive Concrete Type Linings - thin brick concrete formliners

- Consider Clean-and-seal As An Alternate Surface For Indoor Concrete Floorings - concrete formliners thin brick

- Everything To Understand About Concrete Kind Linings - thin brick formliners

- Project Awards - thin brick form liners

- Solutions - concrete formliners thin brick

Why Precast? (Advantages) - thin brick formliners

Advantages of Use Formliners

Most formliner producers have the capability to generate personalized materials, broadening the realms also better for constructing design. Formliners are originally produced from a master mould, which can be established from components located in nature, crafted by an artisan, or through usage of computer system mathematical control (CNC) milling machinery.On conclusion of the master mould for the personalized formliner, the design professional will either authorize the style or recommend alterations. Once accepted, the master mould will ultimately be utilized to cast formliners a precast maker or specialist will certainly use to produce the architectural concrete element. Depending upon the contract in between the formliner supplier and also the task designer or owner, the customized mould may be retired or ended up being the residential property of the task proprietor. This might further enhance uniqueness, especially if the customized formliner is scheduled for that specific job.

New innovation permits the layout specialist to assume also further outside the box. Photoengraved and 3-D relief formliners provide life-like pictures never before possible in concrete or masonry style. There has constantly been a mission to integrate esthetically pleasing aspects right into structure façades. One of the most respected instances are located in very early Greek and also Roman style. Wealth in these 2 cultures was deeply rooted and expressed through lavish building exteriors. These designs were so impressive many elements of modern-day architecture can be traced to those eras. The ornate columns and hand-cut stone building blocks make a bold statement through esthetics, but also provided function. So much 'function' in fact, the grandest of these frameworks are greater than 2 centuries old. The very early developers and also erectors of these old structures were establishing the stage for a 'drab-to-fab' change in structure outside building surfaces.

- Plastic type linings are usually made using a vacuforming process.

- The two slightly conic halves of the mould can be held together with the aid of boards and clamps for casting the baluster.

- A formliner can be an economical method to provide concrete an unique, creative appearance.

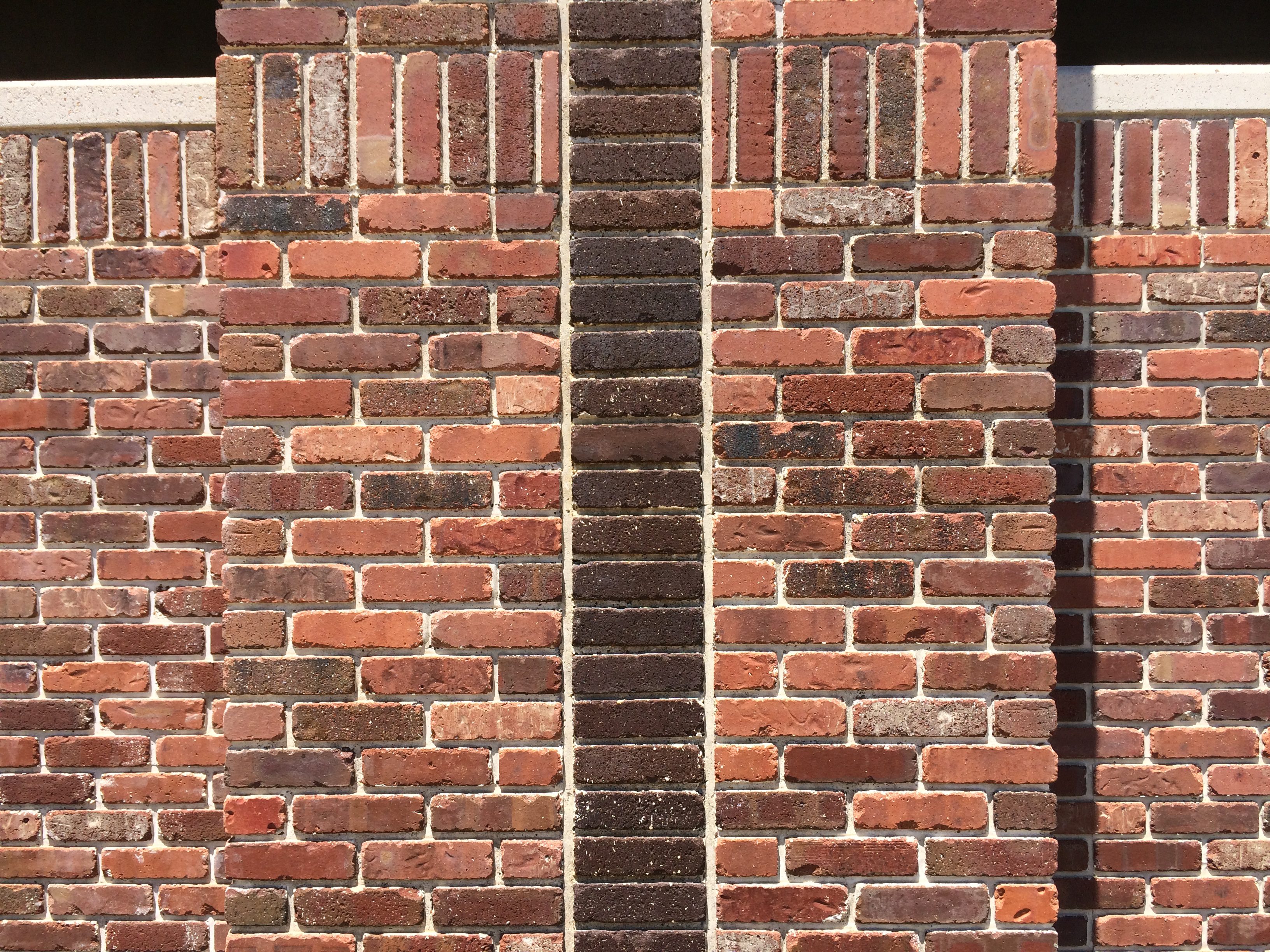

- Replicating block as well as block, 2 of the most traditional building materials is easy.

- Utilizing this method, letter panels can blend in with the wall pattern structure which offers the indicator the striking appearance of a watermark in concrete.

Early constructing style as well as materials were relegated to what was readily offered from the planet. Egyptians made use of straw, mud, plaster, as well as lime to form bricks and mortar in the construction of the pyramids. The Romans made use of a product comparable to contemporary cement and combined it with pet items that functioned as admixtures. Nevertheless, it was not until 1824 when England's Joseph Aspdin developed portland concrete. As the cornerstone in concrete, this product catapulted the style and construction sector onward. The century complying with Aspdin's innovation saw numerous historic firsts within concrete building and construction, from the initial strengthened bridge in 1889 (San Francisco) to the very first skyscraper in 1903 (the Ingalls Building in Cincinnati). Concrete and also concrete stonework systems (CMUs) soon became the building and construction product of option for many designers throughout the globe.

Extended-use, Elastomeric Type Liners From Fitzgerald Formliners - thin brick form liners

With this advancement, came the raised need for patterns, structures, and colours. Coloured concrete was presented in 1915 when Lynn Mason begain creating colour additives for concrete; a half-century later, made patterns came to be possible. With the introduction of formliners, patterned thin brick formliners concrete once attainable through handcrafting could currently be duplicated in a controlled and extra proper fashion while maintaining the timeless appearance borrowed from ancient style. In the 1970s, formliner makers were able to add appearances. Kinds of formliners: Contemporary formliners lend a virtually limitless range of pattern and appearance chances. North American producers provide a typical choice of products, with some supplying greater than 300 options.

In the 1970s and 80s, ribbed patterns were extensively utilized in designs for audio walls, industrial structures, mass transit stations, and also various other various structure outsides. As polyurethane formliners emerged, the ribbed patterns paved the way to more natural and also special patterns. This provided the architect with more alternatives as well as flexibility when making a concrete structure exterior. Patterns and also structures previously just offered by extracting them from all-natural materials are now specifically replicated in formliners. Also one of the most conventional structure materials, brick and also block, have been recreated. Rock, timber, stucco, masonry, and also abstract esthetics can all be integrated in designs.